The machine

Cervo RFE joins our production range in 2016, following extensive testing on a pilot machine. Immediately noticed and admired by users, it goes on to replace mechanical headstock RF5 finishers. Fast and precise adjustments are paired with the quality and efficiency that Sant’Andrea finishers have proudly delivered for years.

The full-length design of the CERVO finisher preserves the advantage of modularity and easy maintenance of the RF generation, while introducing innovative advancements in set-up and operator interface.

Touchscreen

Easy-to-read 15” display showing machine status during operation, number and specifications of the inserted request, list of tensions and recording parameters, ratches used (input and drafting), production data and efficiencies, motor power consumption, motor temperature, causes of stoppages, diagnostics and performance, maintenance schedule, number of bobbins produced.

Easier maintenance

Independent rubbing boxes, quick and easy apron replacement, production possible even without a rubbing element, disassembly and replacement of the entire module for maintenance purposes, easy access to the inside of the boxes for inspection, modular draft group, reduced lubrication points, no need for oil changes in mechanical gearboxes, reduced number of timing belts and wear-prone belts.

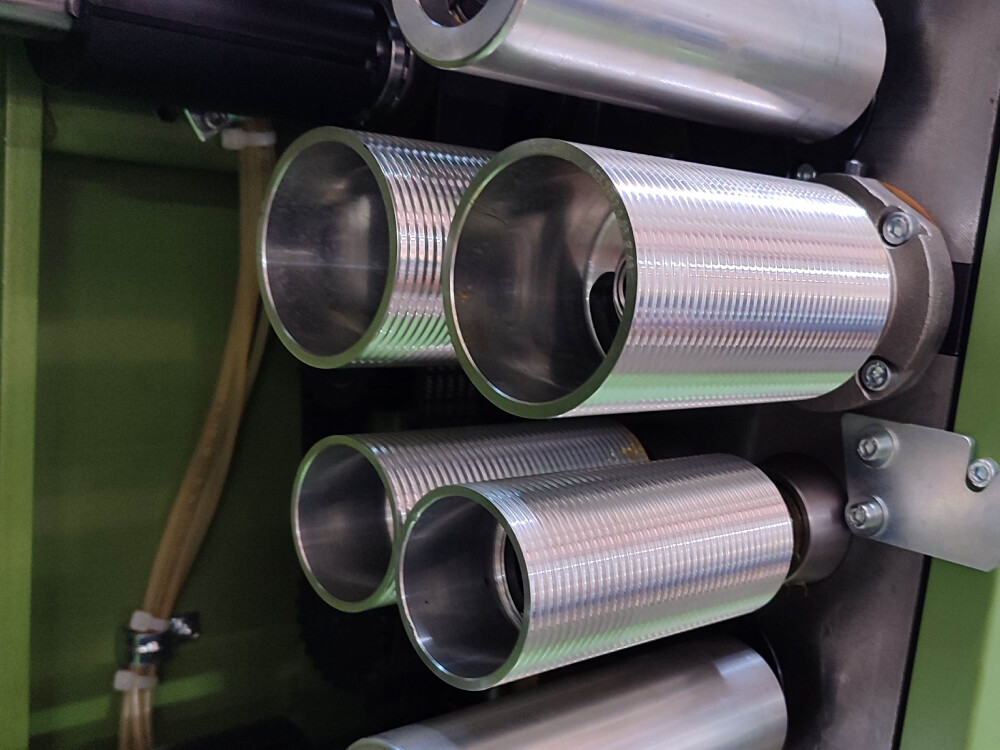

Double rubbing

Double rubbing has always been a key strength of Sant’Andrea finishers, playing a fundamental role in ensuring the resistance and compactness of the rovings.

Electronic control

Electronic control has enabled a more precise optimisation of strokes, tailored to the materials being processed – from the simplest fibres to the most complex blends.

With the release of the mechanical system, rubbing strokes can reach up to 16 strokes per metre (8 per field), with an output speed limited to 140m/min.

The benefits associated with roving resistance are particularly clear in the production of premium or low-cohesion materials (such as cashmere and silk) or synthetic fabrics without crimped fibres (meraklon-nylon-polyester, etc.), viscose, and specific blends.

Headstocks and adjustments

The motorisation has been engineered to directly link the motor axis to the relevant shafts along the entire length of the machine. Gear reducers are mounted directly onto the motor with carefully selected reduction ratios, ensuring consistently high performance and low energy consumption by the motor torque.

The main motor adjustments, that can be customised via the touchscreen, include the speed of the creel, feeding cylinder, draft group and rolling mill, rubbing apron rotation and rubbing strokes, bobbin winder cylinder and twister speed (with adjustable crossing angle).

The final step before the yarn

The finisher represents the last stage of preparation before spinning. At this point, no further blending occurs and the fibres must be handled with the utmost precision.

The search for the ideal adjustment for each fibre type and weight is achieved by fine-tuning speeds and tensions – unlike in the past, when gears restricted the range. Speed changes rapidly take place while the machine is running, allowing immediate evaluation of their impact on both the machine and the rovings.

The best set-up can be saved, making it easy to recall configurations whenever the same batch needs to be repeated.

Modular machine with 8 to 24 heads.

Creels available for 700/800mm diameter cans, with single or double sliver configurations.

Open roller creel, with the option to include driven rollers.

290 or 330mm roving winding tube.

Missing rovings are detected by photocells and shown on the touchscreen to identify the corresponding head.

Safety photoelectric barrier for operator protection.

Safety sensor for bobbin tipping detection.

Detailed graphical warning for doffing stoppages.

Interface for the automation of bobbin release on demand.

Applications throughout the supply chain

Cervo represents the most crucial and delicate step in the preparation for the spinning stage.

The double rubbing, a Sant’Andrea Novara innovation, guarantees the perfect balance of quality and productivity.

Wool and noble fibres

Applications

In the extra-fine fibre sector, double rubbing by Sant’Andrea Novara is undeniably the ideal solution. The double apron ensures superior preparation of rovings, even with the most premium and delicate fibres.

RFEA / CERVO-A

- A-type draft control.

- Minimum ratch: 25mm.

- Recommended for fine counts.

RFEA-RFEB / CERVO-A CERVO-B

- A- or B-type draft control.

- Type A: up to 6Nm counts.

- Type B: from 0.8Nm counts.

Synthetic fibres

Applications

Originally developed for noble fibres, double rubbing takes full advantage of the double apron features for processing synthetic materials. The false twist on the roving ensures high performance in terms of production capacity.

RFEB / CERVO-B

- B-type draft control.

- Feeding twin cylinders for optimal control.

- Minimum ratch: 33mm.

- Recommended for medium counts and high production volumes.